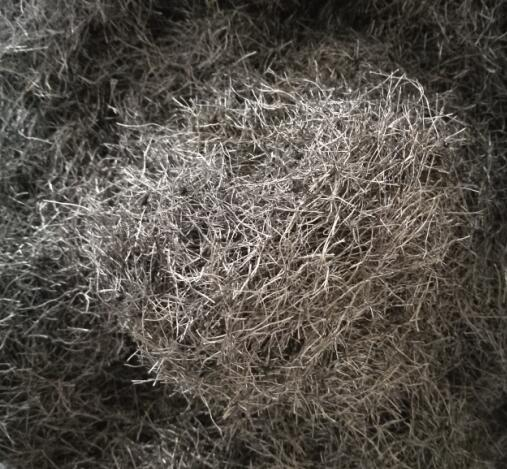

Waste tires contain two kinds of steel wires, one is the thick steel wire at the inner mouth of the tire, and the other is the capillary steel wire in the carcass. First of all, let's talk about the machine that separates the thick steel wire of the tire inner mouth, the equipment that needs to be used is the tire steel rim separator, the tire steel rim separator is also called the tire wire milling machine, and the worker only needs to put the tire inner mouth to the guide groove during the operation, and the machine can be started by jogging the button, and the steel wire and rubber are separated by rolling through two pairs of rollers, without changing the shape and physical properties of the steel wire; The second is to deal with the capillary steel wire in the carcass, which requires the use of magnetic separation equipment, which is added to the waste tire rubber powder production line as auxiliary equipment, and separates the capillary steel wire in the rubber powder while making the rubber powder.